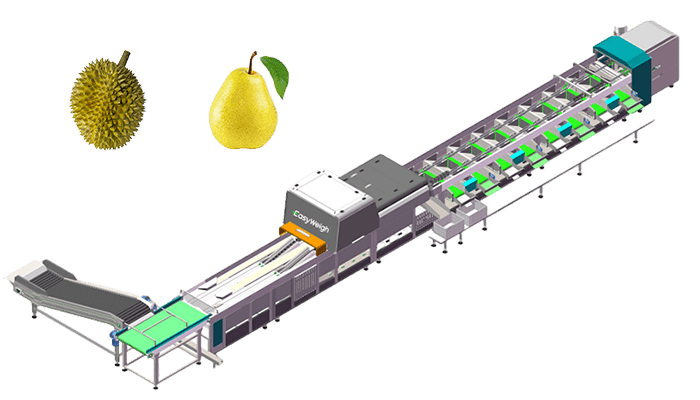

Industrial automation has become a cornerstone in modern food processing, and companies like WEIGHT SORTING play a significant role in this evolution. Their optical sorting machine for large-sized fruit is specifically designed to handle items such as watermelons and melons with precision. By integrating high-resolution imaging with AI-powered analysis, this system enables efficient grading and inspection, helping operations maintain consistent product quality. The technology reduces human error, accelerates processing, and supports large-scale production needs, making it a reliable choice for manufacturers seeking automation.

Enhanced Efficiency Through Technology

One of the key advantages of the optical sorting machine is its ability to streamline workflow. WEIGHT SORTING has developed a system that automatically detects size discrepancies, color variations, and surface imperfections on fruit. This level of accuracy ensures that only products meeting quality standards proceed through the supply chain. Automation reduces labor dependency and speeds up sorting operations, which is particularly valuable for facilities managing high-volume fruit processing. The system’s AI capabilities also allow it to learn and adapt, providing consistent performance over time.

Reducing Waste and Optimizing Output

By utilizing precise inspection mechanisms, WEIGHT SORTING’s optical sorting machine minimizes waste caused by human oversight. Fruits that do not meet quality criteria are efficiently separated, preventing defective items from reaching packaging lines or markets. This separation improves resource utilization and contributes to more sustainable processing practices. Moreover, the machine can handle varying sizes and weights, which makes it flexible for different batches and fruit types, enhancing overall operational adaptability.

Reliable Integration for Industrial Automation

Implementing an optical sorting machine from WEIGHT SORTING supports broader automation strategies within industrial facilities. The system can integrate smoothly with existing production lines, offering data tracking and monitoring functions that inform operational decisions. Its user-friendly interface and consistent sorting performance provide manufacturers with a dependable tool to maintain quality control and operational efficiency. By reducing manual intervention, facilities can achieve more consistent results while optimizing labor and time resources.