The medical industry demands components that prioritize safety, sterility, and microscopic accuracy. From surgical implants to diagnostic devices, even minor flaws can impact patient outcomes. CNC machining solutions have emerged as a cornerstone of medical manufacturing, enabling the production of complex, high-precision parts with unmatched consistency. Leichman, a HOSTON sub-brand specializing in advanced CNC systems, provides tailored CNC machining solutions for medical applications, combining cutting-edge technology with rigorous quality control.

Achieving Biocompatible Surface Finishes

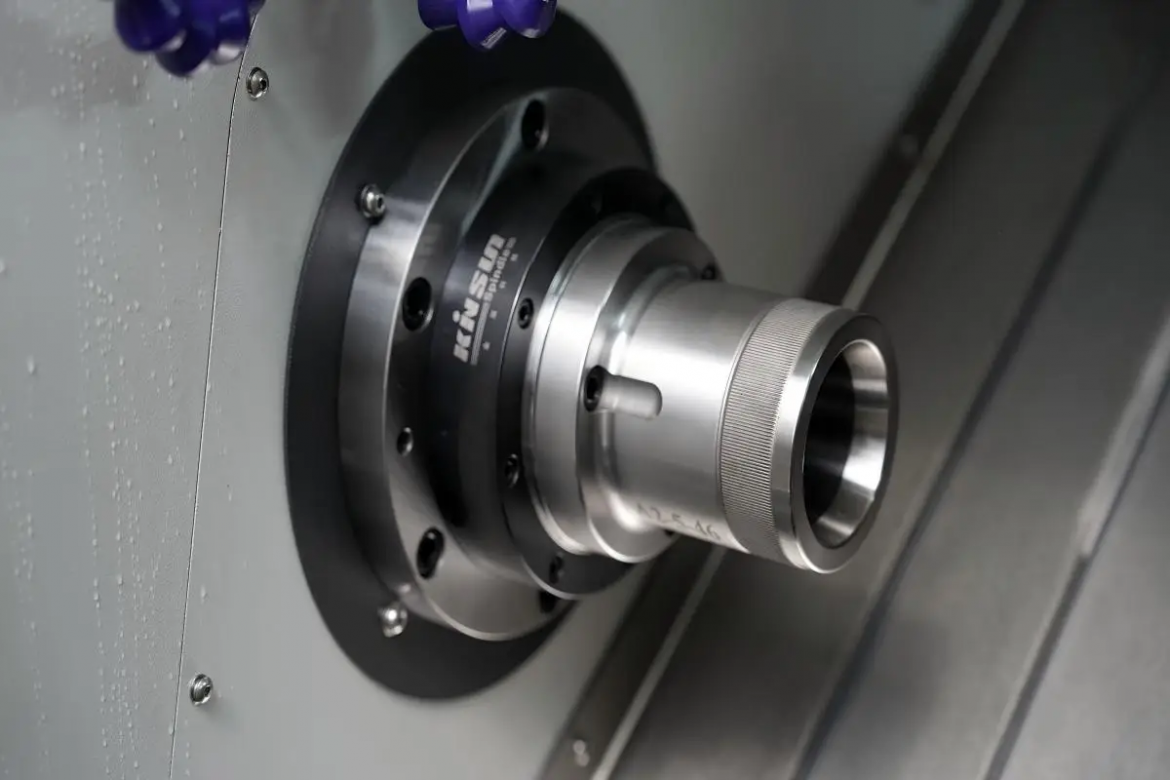

Medical devices often require parts with ultra-smooth surfaces to prevent bacterial adhesion or tissue irritation. Leichman’s CNC machines utilize high-speed spindles and precision tooling to achieve surface roughness, critical for implants like titanium hip joints or stainless-steel surgical instruments. Their systems incorporate Syntec controllers and Japanese THK guide rails, minimizing vibrations to ensure flawless finishes even on delicate geometries.

Supporting Small-Batch and Customized Production

Patient-specific medical devices, such as prosthetics or dental implants, demand flexibility in manufacturing. Leichman’s CNC machining solutions for medical accommodate low-volume orders, including single-unit production, without compromising accuracy. Their machines support customizable parameters like spindle speed and tooling paths, enabling rapid adaptation to unique patient anatomies. This agility reduces lead times, allowing healthcare providers to deliver personalized solutions faster.

Ensuring Compliance with Stringent Standards

Medical equipment must adhere to regulations like ISO 13485 and FDA guidelines, which mandate traceability and process validation. Leichman’s CNC systems integrate real-time monitoring and data logging, documenting every stage of production. Their free consultation services further assist clients in navigating compliance requirements, from material selection to sterilization-compatible finishes.

Conclusion

CNC machining solutions are transforming medical equipment manufacturing by delivering precision, adaptability, and regulatory compliance. Leichman’ s expertise in high-performance CNC systems positions them as a trusted partner for industries requiring components that meet the strictest healthcare standards. Whether producing off-the-shelf instruments or customized implants, their CNC machining solutions for medical ensure reliability while optimizing costs—a vital combination for advancing patient care in an evolving global market.